Help - COSHH Section 4

Risk Control Measures

Section 4 deals with the risk control measures put in place to control the hazards and risks identified in sections 2 and 3. It contains typical risk control measures which can be applied to eliminate or minimise the risk of a particular procedure or hazardous property of a substance.

These should NOT be seen as the only methods of control and just because other means of control are not listed does not mean they should not be considered. Any additional control measures identified must be included as part of the safe method of work in Section 11.

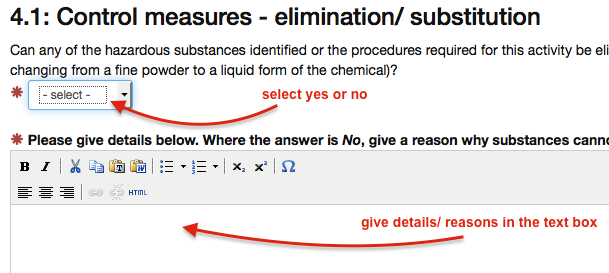

Section 4.1 Elimination/Substitution

Select yes or no, then give details

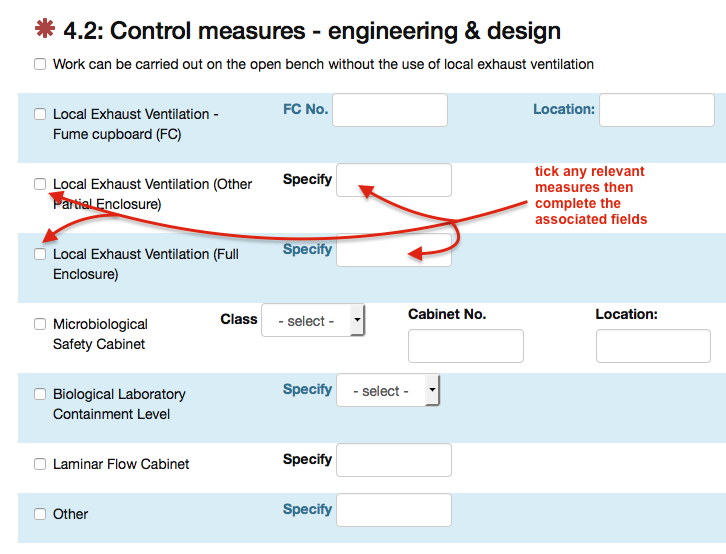

Section 4.2 Engineering and Design

This section deals with the engineering controls designed to remove hazardous substances at source.

On-the-Bench Activities

Consideration must be given to which activities are of sufficiently low risk to be carried out on the open bench. Substances which may fall under this category include those that are:

- Non-hazardous via the inhalation route

- Used in small quantities

- Non-volatile

- Non-dusty

Simple additional containment measures such as using work trays can limit spillages and drips from pipetting.

Full or Partially Enclosed Systems

Those parts of the activity that require the use of a fume cupboard or other form of local exhaust ventilation (LEV) need to be identified.

These will typically be activities involving:

- large quantities of volatile or flammable liquids

- substances which are hazardous via the inhalation route

Where LEV is employed it needs to be appropriate for the task and where relevant, located and installed in accordance with British / European standards. Refer to Local Rules on Installation and Use of Local Exhaust Ventilation and Local Rules on the Safe use of Microbiological Safety Cabinets which can be found at Safety, Health and Wellbeing pages.

Section 4.3 Administrative Controls

These are many risk control measures which are written down to provide instruction or guidance to the operator to carry out the job safely and may include:

- Risk assessments.

- Systems of Work (SOWs) or Standard Operating Procedures (SOPs)

- Special written procedures.

- Local rules and guidance documents

- Signage

- Permit-to-Work authorisations.

Ensure these are recorded in the safe method of work in section 11 and all operators involved in this task are given training or guidance on how to follow these written instructions.

Section 4.4 Instruction and Training

In this section you should include:

- the level of instruction and training required for the task

- any specific information relating to hazardous substances that needs to be shared with operators

This is particularly relevant where significant hazard(s) associated with either the substances or task involved have been identified. (Noted in Section 2.4).

Note any special training required to ensure that persons involved in the work activity can operate safely. This will ensure that persons can understand and comply effectively with the safe method of work, where this has been formulated and recorded in Section 11.

Training records should be maintained locally within the department.

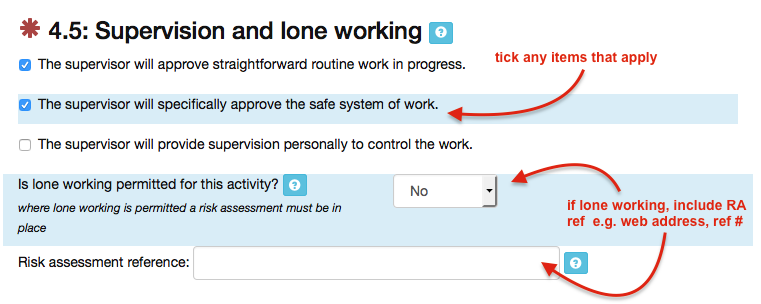

Section 4.5 Supervision and Lone working

1) Supervision is dependent on the level of risk associated with the task and the level of experience of those involved. The supervisor must be satisfied that operators are competent to carry out the work, everything is being complied with and safe methods of work are being followed.

PIs and Supervisors are expected to monitor whether controls are in place, operating correctly and that adequate training has been carried out.

2) Where lone working is permitted it must be included in the risk assessment which covers this task, where the hazards and risks can be fully assessed. If yes, enter the reference number for the risk assessment which deals with lone working. Also see Section 9.

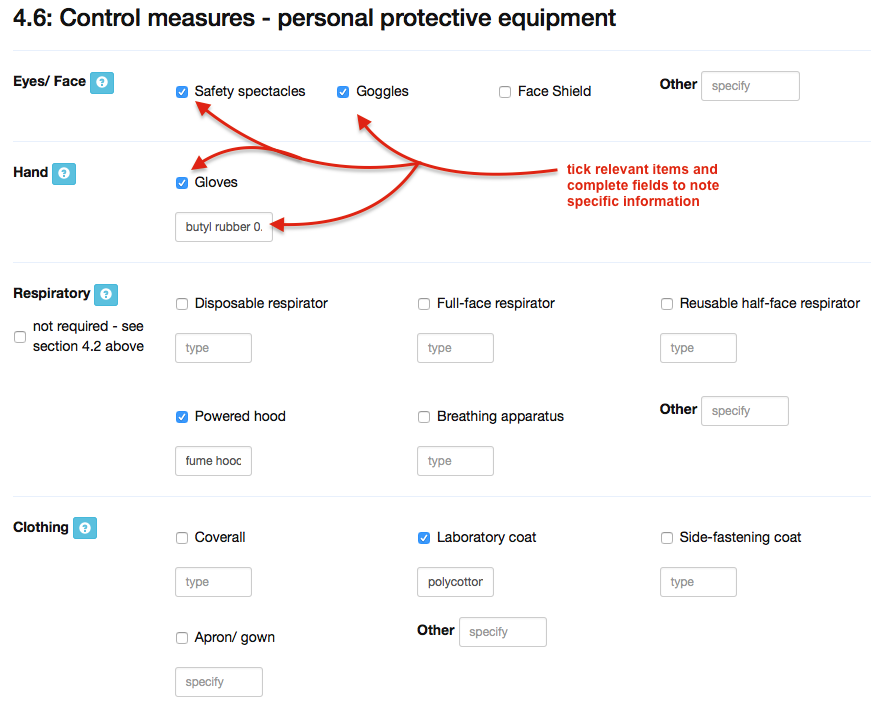

Section 4.6 Personal Protective Equipment

Remember that personal protective equipment is considered the last resort for controlling hazards to health. However it plays an imptortant role in the laboratory provided the correct type is used. See also Local Rules on Personal Protective Equipment for more specific advice on the different types of PPE available.

- Eyes/Face: Include details of the type of protection being provided e.g. EN166, Chemical or metal splash, dust, projectiles, gas and vapour, radiation

- Hand: Consider breakthrough rates and permeation rates of gloves for the different substances in use. Use this information to identify the most suitable type of glove.

- Respiratory: Specify the type of mask or filter in use e.g. FFP2 or AXB2

- Clothing: Specify the type of overall/lab coat to be used e.g. chemical, fire, static resistant; Howie coat etc.

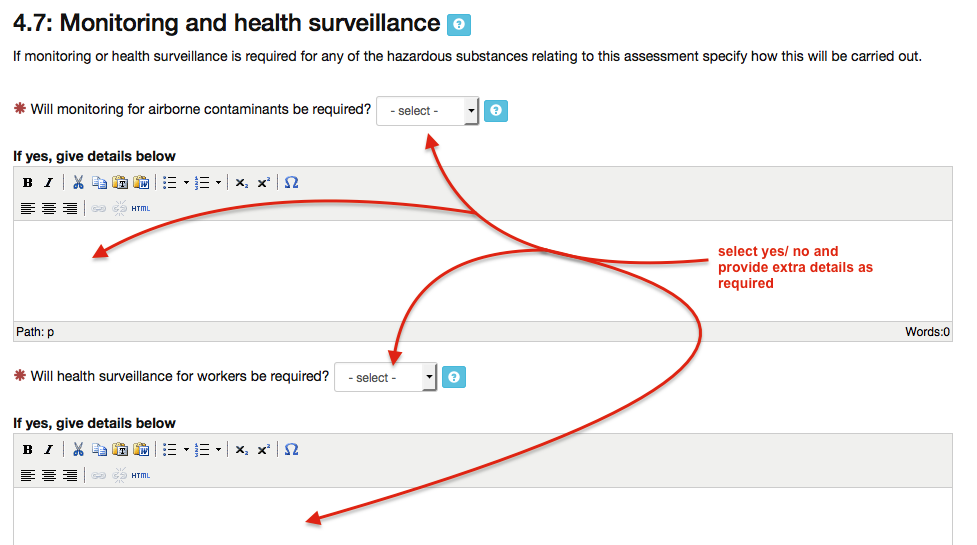

Section 4.7 Monitoring and Health Surveillance

Monitoring

Workplace exposure monitoring should be requested:

- where there is uncertainty about the levels of airborne contaminants generated by a work activity;

- the consequences of exposure are significant;

- and where there is a need to confirm the effectiveness of the risk control measures used.

In most cases personal and atmospheric monitoring should not be necessary, providing sufficient thought has gone into ensuring the adequacy of risk control measures and these measures are properly used and maintained. Where monitoring has been carried out include details within the COSHH form of the results and information provided to staff and students.

Exposure monitoring is arranged via Safety, Health and Wellbeing.

Health Surveillance

Specific types of substances require health surveillance and Occupational Health Service should be contacted in the first instance for further information.

also see:

- section 1

- section 2

- section 3

- section 4

- section 5

- section 6

- section 7

- section 8

- section 9

- section 10

- section 11

- section 12